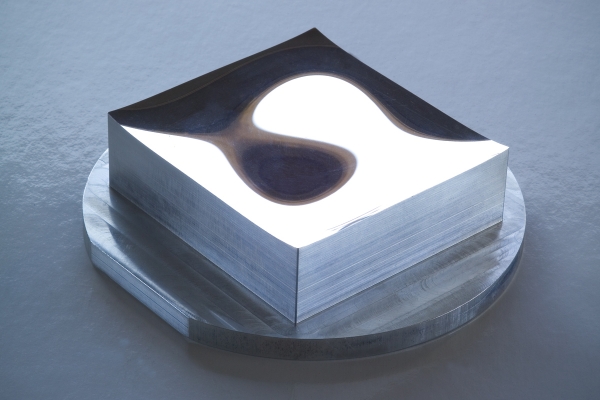

Freeform Optics

Challenging freeform or anamorphic optics are created at CMM Optic for use in imaging applications, head up displays (HUD) and head mounted displays (HMD).

CMM Optic is one of the few optic manufacturers with the experience, machinery and metrology to create freeform optics accurately and with proof of performance.

Key Capabilities: Our multi-axis diamond-turning machines allow for fully customized optic solutions. Because of our world-class metrology lab and highly experienced multi-axis CAD operators, we manufacture non-rotational aspheres, amorphic and anamorphic optics for military, imaging and aerospace uses.

Range of capability:

- Diameter: 0.020” to 17” (0.5 mm to 450 mm)

- Thickness: 0.13” to 3” (3 mm to 75 mm)

- Terms: Up to 231 (X^20, Y^20)

- Cut to CAD Model

- Minimum Curvature: 0.002” (0.050 mm)

- Surface Finish: As low as 20 Angstroms

- Surface Figure: 0.5 micron

Coatings:

- Protected Aluminum

- Protected Gold

- Bare (unprotected) Gold

- UV Enhanced Aluminum (250 – 450 nm)

- Protected Silver (450 nm – 20 um)

Typical Base Materials:

- Aluminum

- Brass

- Nickel-Plated Stainless Steel

- Nickel-Plated Invar

- Cupronickel

- Copper

- PMMA (Polymer

Searching for a build-to-print, or off-the-shelf solution? We have you covered with our Perfect Fit Optics.

Ask about how Perfect Fit freeform optics can help your project!

Don’t see exactly what you need here? Let us know, we very likely are able to create it for you.