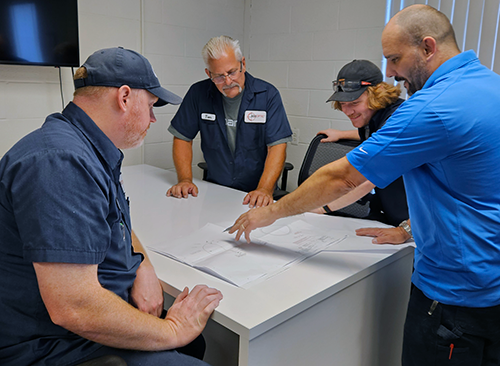

Advanced Optics Manufacturing Team

Our Advanced Optics Manufacturing Team is dedicated to support prototype-to-production from start to finish. The race to develop and place instruments in the field is only getting shorter in today’s competitive optics marketplace.

Our Advanced Optics Manufacturing Team

Our dedicated group of highly experienced and skilled engineers, machinists, technicians, and

project managers get proof-of-concept and prototype projects off the ground for defense,

aerospace, and semiconductor applications. This team represents CMM Optic’s fastest way to

support your project at the outset, from design to concept to final production, as they are

dedicated to your project’s success.

CMM Optic’s fast-steering mirrors, air bearing systems and scanners, reflective/refractive optical

assemblies are found in today’s large/small telescopes, test rigs, laser systems, HUD systems, and range finders/targeting systems globally.

Providing solutions at the production level.

We set aside some of our site capacity to help develop the next generation of products,

including our 5-axis milling, mill-turn, diamond turning, inspection, and lens alignment equipment

capacity. Only the highest precision results, documented with our world-class metrology suite,

are created daily on our manufacturing floor.

Only the best people.

We have pulled from our most experienced and creative team members to build this fast-response team which can nurture a project from those critical prototypes all the way to production volumes.

Project Management

Even in the early stage of scheduling the initial quote to the final measurement and inspection of production parts, our goal is always to give 100% on-time delivery and 98+% part acceptance.

CMM Optic is AS9100 and ISO 9001 certified by NSF-ISR at both Troy and Rochester Hills, Michigan, facilities.

We aren’t bigger, just better.

Redefining What Is Possible.

"CMM Optic has gone above and beyond expectations in essentially all aspects of the business. They are extremely thorough, meticulous, and communicative. The quality of product is top-tier. CMM Optic always follows through on various requests, all the way from design/technical feedback to purchasing expedites. We have the utmost confidence when doing business with CMM Optic."

“We have had a couple of rough moments getting our side of the system, which you are making parts for, work. Problems on our end, not yours. A couple of different times now our solution to get up and running has been to pull parts off the machines and try different ones. There is almost no way I can communicate how complex these machines are and the intricacies of what they are performing for us, even to you, who have the drawings in front of you. What these machines are doing is possibly more complex than what the products do they produce.

And so, each one we make is pretty much (fully custom) and everyone holds their breath until each is completed and verified. In all this complexity and suspense, we have now, at least twice troubleshot our problems by pulling parts off the machines and replacing them with other parts you've sent us and every time the change over showcases the amazing precision and consistency CMM delivers and has also elevated you and I both to semi-hero status.

These swaps show the issue isn't (CMM), and eliminates all options except the ultimate solution for me and so we are up and running quickly after such an exercise. One reason people have become comfortable with these exercises is because they have confidence in CMM to save us if our team here ruins a part or breaks something during our fiddling around with everything.”